Grab Up To 70% Off In Our January Sale!

Free delivery on orders over £499*

The World’s First 100% Recycled Ceramic Basin

The World’s First 100% Recycled Ceramic Basin

VitrA has designed the world's first 100% recycled ceramic basin made with sustainable materials and efficient production. Find out how they are setting a new standard in sustainable and eco efficient design within the industry.

Crafted from 100% recycled ceramic waste

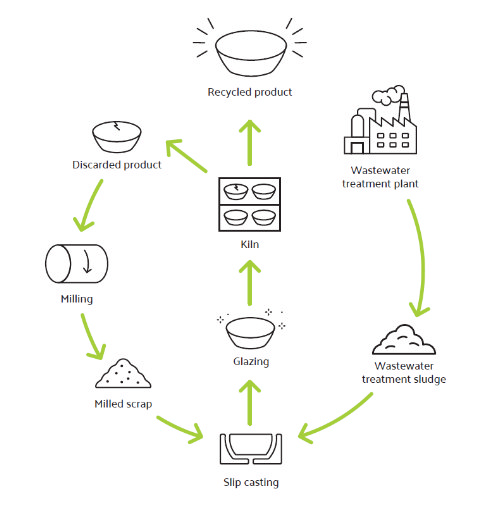

Made using broken and discarded ceramics, along with other waste materials from the manufacturing process that would typically end up in landfill, VitrA’s recycled ceramic washbasin sets a new standard in sustainable design within the industry. The entire basin, apart from the glaze, is produced from nearly 100% recycled waste materials that are generated and disposed of during the ceramic sanitaryware manufacturing process.

When ceramic is left in a landfill, it can take more than 1000 years to decompose. Which means that landfills could quickly become overrun with ceramic waste. There are approximately 68 million tonnes of ceramic waste sent to landfills annually in the UK. The recycled ceramic washbasin embodies the principles of circular manufacturing, which means that all of this ceramic waste is turned into a valuable resource.

Sustainable Manufacturing Process

A life cycle assessment, conducted by VitrA, found that the production of the recycled washbasins minimises environmental impact on fossil fuel usage and global warming by a significant 30% per product. The sustainable manufacturing process achieves approximately 5kg of raw material savings per basin (a 36 percent improvement), and a 2.48 kWh reduction in electricity usage per basin (a 38 per cent enhancement), due to the decreased reliance on raw materials.

This means that when basins are produced using recycled ceramic waste, we will not only be able to keep our landfills clear of wasted ceramic, we will also be able to reduce our carbon footprint by minimising fossil fuel usage and energy consumption.

Attractive Design

Despite their sustainable production, these recycled basins still give the same luxurious looks that you would expect from any modern basin. The basin is available contemporary round shape with a matt taupe finish. The slightly textured finish offers a unique aesthetic which increases the visual and tactile impact of the recycled material.

The bowls also come with matching ceramic free-flow waste for added visual impact. Every detail, even down to the packaging of a 100% recycled box, is certified by the Forest Stewardship Council (FSC). Demonstrating the commitment to reducing waste where possible and conserving natural resources.

Megan

Megan is an expert bathroom blogger, she enjoys writing helpful DIY articles and bathroom inspo blogs. As well as specialist bathroom advice, Megan also shares expert how-to blogs with step by step guides.